Ball screw, like lead screw, converts rotary motion into linear motion. The device consists of a threaded shaft and a ball nut.

Ballscrews are often a first choice for linear-motion applications because the use of recirculating ball bearings provides high efficiency, load capacity, and positioning accuracy. Furthermore, ballscrews generally provide equal or better load capacity than leadscrews, and so are a better choice when load requirements exceed leadscrew capabilities.

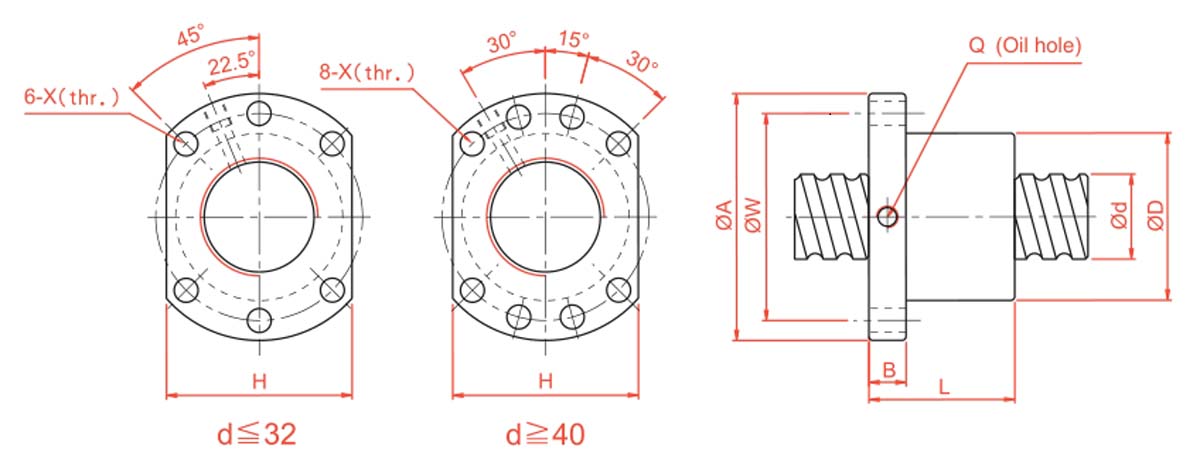

| Model No | d | i | Da | Dimension | Loading rating | K kgf/μm |

|||||||||

| D | A | B | L | W | H | X | Q | n | Ca(kgf) | Coa(kgf) | |||||

| SFU1605-4 | 16 | 5 | 3.175 | 28 | 48 | 10 | 45 | 38 | 40 | 5.5 | M6 | 1X4 | 1380 | 3052 | 32 |

| High Reliability | FON applies stringent quality control standards on every production process. With proper lubrication and use, trouble-free operation for an extended period of time is possible. |

| Smooth Operation | The high efficiency of ball screw is vastly superior than conventional screws It takes less than 30% torque to make the linear motion into rotary motion. |

| High Rigidity and Preload | The ball screw of FON is designed with Gothic arch groove, which makes the screw easy to rotate even using minimum axial play. To make the rigidity more appropriate to using condition, you can change the preload between one or two screw nuts to reduce axial play. |

| High Durability | The ball screw of FON is designed with Gothic arch groove, which makes the screw easy to rotate even using minimum axial play. To make the rigidity more appropriate to using condition, you can change the preload between one or two screw nuts to reduce axial play. |